Instruments

PLASTIC LIMIT

MODEL: BE-GT-002 IS 2720 (PART-VII) ASTM D 427, BS 1377, AASHTO T 92. Shrinkage limit is the maximum water content at which a reduction in water content does not cause an appreciable reduction in volume of the Soil Mass. At shrinkage limit, on further reduction in water, air enters in to the voids of soils and thus keeps the volume constant. The apparatus can be used to determine shrinkage limit and to calculate other shrinkage ratio, shrinkage index and volumetric shrinkage.

Specification :

Set consists of one each :-

I) Porcelain evaporating dish,

ii) Shrinkage dish,

iii) Glass cup,

iv) Perspex plate with three metal prongs,

v) Flexible spatula 100mm,

vi) Glass cylinder,

vii) 25ml x 1ml, supplied without mercury

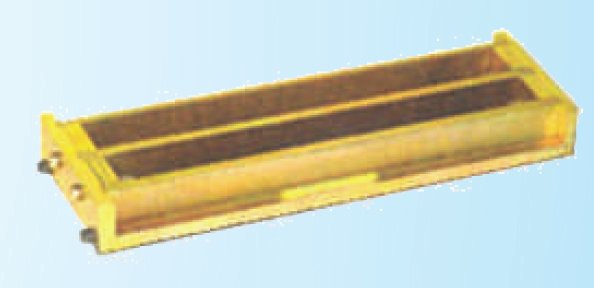

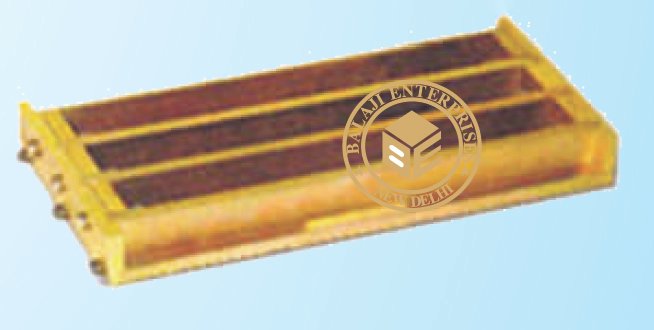

LINEAR SHRINKAGE MOULD

MODEL: -GT-003 BS 1377-2 A simple mould which is filled with the soil under test. This is then dried and the resulting decrease length of the specimen measured is expressed as the linear shrinkage. It is 25mm Dia. x 12.5mm Height x 140mm Length.

SOIL CONE PENETROMETER

MODEL: -GT-004 IS 2720 (PART IV) For determining the liquid limit of soils. This is specially useful to obtain reliable and accurate results of those soil which have low plasticity index. The percentage moisture contents determined when cone with half angle for 15-30 minutes under a total sliding weight of 148 gm penetrates 25mm gives the liquid limit.

SOIL HYDROMETER

MODEL: -GT-005 ASTM D 422 AASHTO T 88, BS 1377-2. Used for grain size analysis of soils where more than 10% of the material will pass through 75 microns B.S. sieve. Manufactured from clear transparent glass having uniform clarity throughout the upper end on which density scale is engraved. The scale range is 0.995 to 1.030 0 density (gms./cc) at 27oC smallest division on the scale is 0.0005.

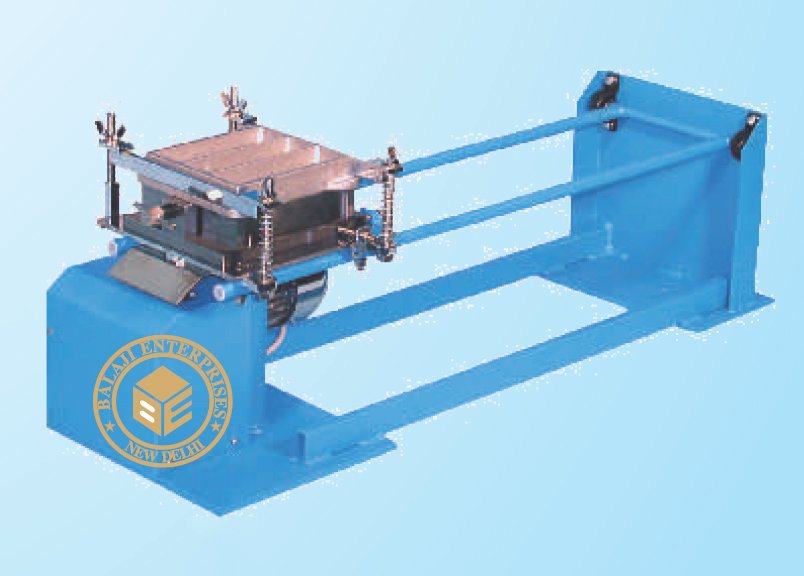

LIQUID LIMIT DEVICE

MODEL: -GT-006 IS 2720 (PART V), BS 1377-2 , ASTM D 4318 Casagrande method in mechanical form is known as liquid limit method and has been in use for soil mechanics for a number of decades. The liquid limit data of soils is useful to correlate mechanical properties of soil, such as compressibility and lower shear strength. Liquid limit is the water content at which soil passes from zero strength to an infinite strength, hence the true value of liquid limit cannot be determined. For determination purpose liquid limit is that water content at which a part of soil, cut by a groove of standard dimensions, will flow together for a distance of 1.25cm under an impact of 25 blows in a standard liquid limit apparatus. The soil at the water content has some strength which is about 0.17N/cm. sq. (17gms/sq.cm.) . At this water content soil just passes from liquid state to plastic state. It consists on a brass cup held on an adjustable bracket. The cup can be adjusted for a fall of 1 cm and can be raised an dropped on a rubber base of standard hardness by cam action. Complete with one Casagrande grooving tool, one ASTM grooving tool and a height gauge block.

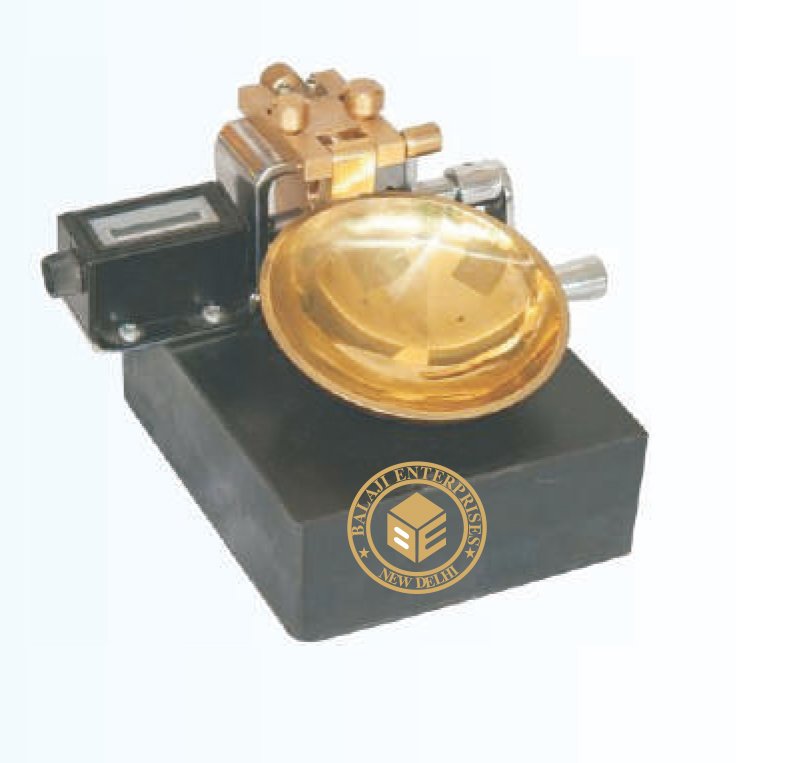

LIQUID LIMIT DEVICE (WITH COUNTER)

MODEL: -GT-007 IS 2720 (PART V), BS 1377-2 , ASTM D 4318 Casagrande method in mechanical form is known as liquid limit method and has been in use for soil mechanics for a number of decades. The liquid limit data of soils is useful to correlate mechanical properties of soil, such as compressibility and lower shear strength. Liquid limit is the water content at which soil passes from zero strength to an infinite strength, hence the true value of liquid limit cannot be determined. For determination purpose liquid limit is that water content at which a part of soil, cut by a groove of standard dimensions, will flow together for a distance of 1.25cm under an impact of 25 blows in a standard liquid limit apparatus. The soil at the water content has some strength which is about 0.17N/cm. sq. (17gms/sq.cm.) . At this water content soil just passes from liquid state to plastic state. It consists on a brass cup held on an adjustable bracket. The cup can be adjusted for a fall of 1 cm and can be raised an dropped on a rubber base of standard hardness by cam action. Complete with one Casagrande grooving tool, one ASTM grooving tool and a height gauge block. Same as above but fitted with a counter to register the number of blows.

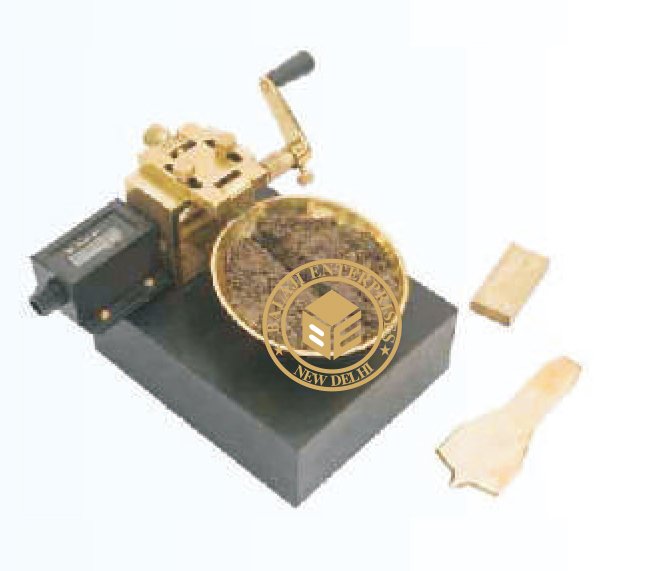

LIQUID LIMIT DEVICE (WITH COUNTER)

MODEL: -GT-007 IS 2720 (PART V), BS 1377-2 , ASTM D 4318 Casagrande method in mechanical form is known as liquid limit method and has been in use for soil mechanics for a number of decades. The liquid limit data of soils is useful to correlate mechanical properties of soil, such as compressibility and lower shear strength. Liquid limit is the water content at which soil passes from zero strength to an infinite strength, hence the true value of liquid limit cannot be determined. For determination purpose liquid limit is that water content at which a part of soil, cut by a groove of standard dimensions, will flow together for a distance of 1.25cm under an impact of 25 blows in a standard liquid limit apparatus. The soil at the water content has some strength which is about 0.17N/cm. sq. (17gms/sq.cm.) . At this water content soil just passes from liquid state to plastic state. It consists on a brass cup held on an adjustable bracket. The cup can be adjusted for a fall of 1 cm and can be raised an dropped on a rubber base of standard hardness by cam action. Complete with one Casagrande grooving tool, one ASTM grooving tool and a height gauge block. Same as above but fitted with a counter to register the number of blows

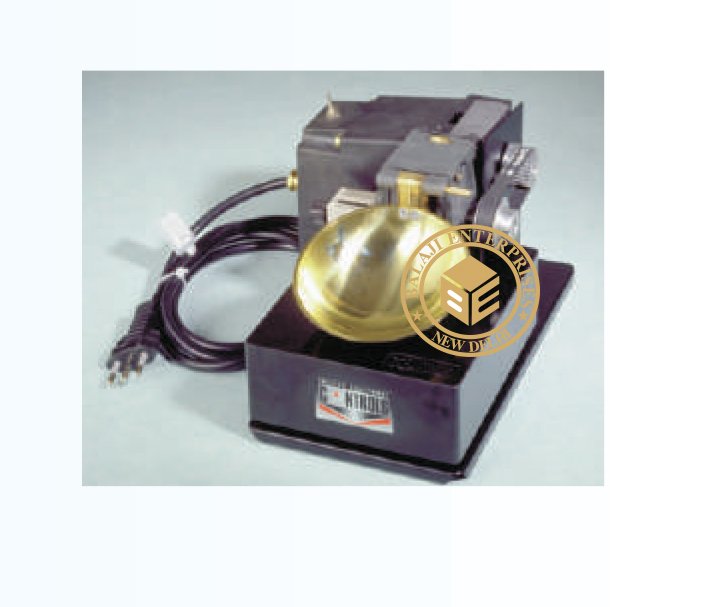

LIQUID LIMIT DEVICE (MOTORIZED)

MODEL: -GT-008 Same as above but fitted with a motor geared down to give approximately 120 rpm. Suitable for operation on 230 V A.C., Single Phase, 50 Cycles. SPARES : Casagrande grooving tool. ASTM grooving tool, height block, 1cm high.

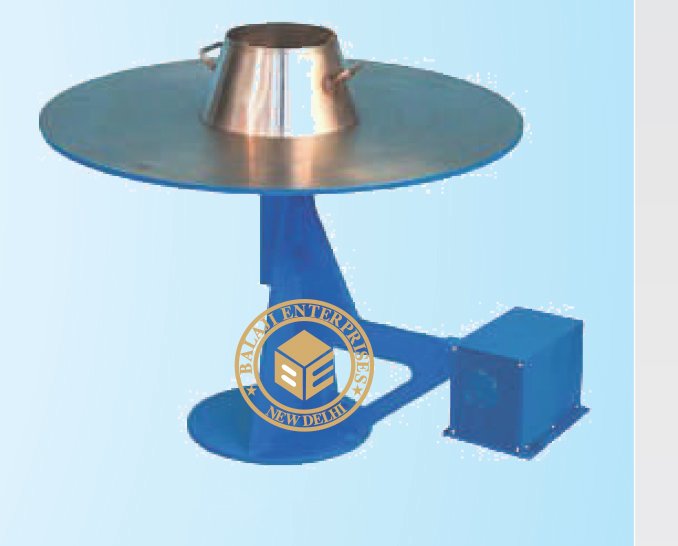

MARSH CONE

MODEL: -GT-009 ASTM D 2419, AASHTO T 176 This cone is used to find out viscosity of bentonite slurry and similar material. The marsh cone is 6 inch in diameter at the top and 12 inch long, and tapers to join a tube 2 inch long and 3/16 inch inside dia. The capacity of the funnel is 1500cc. Time in seconds required to flow out 1000cc of slurry from cone is measured as funnel viscosity of the material.

MUD BALANCE

MODEL: -GT-010 ASTM D 2419, AASHTO T 176 Designed to find out specific gravities of semi liquids like mud and other liquids having densities in the range 0.8 to 2.5. It has a stainless steel bam calibrated specific gravities from 0.8 to 2.5. A stainless steel cup with lid and overflow vent is fitted on one side of the beam. A counter weights with cursor slides over the graduated scale. The beam has a knife-edge at centre which rests in a fulcrum fitted in the stand. Leveling screws and spirit level are fitted to the stand.

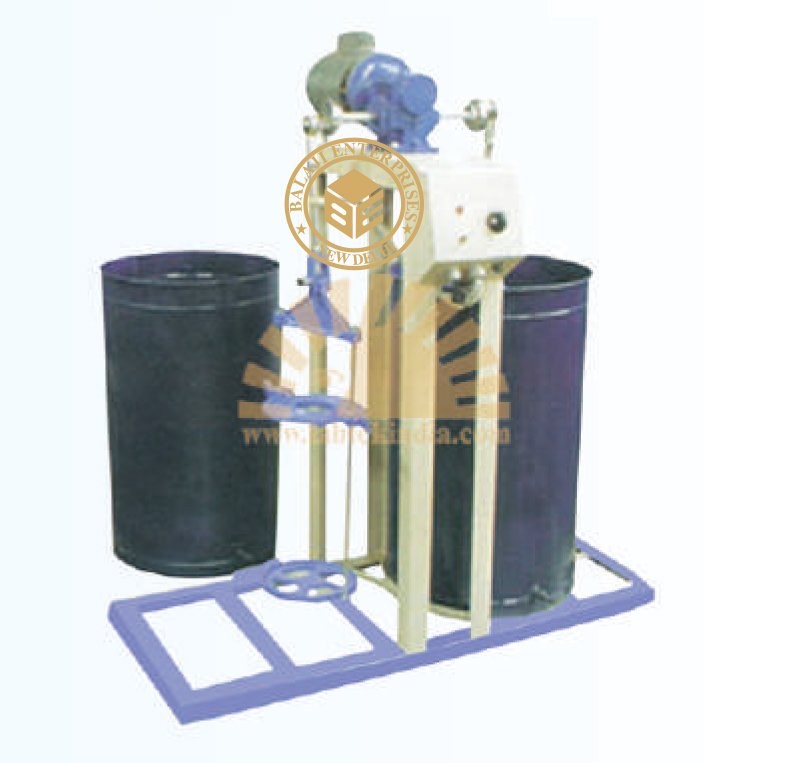

HIGH SPEED STIRRER

MODEL: -GT-011 IS 2720 (PART IV) This is for mechanical analysis and also other laboratory applications for stirring Speed approximately 4000 R.P.M. under load. A dispersion cup is supported on a rest on the stand of the stirrer and has a removable baffle. For operation on 230V A.C. supplied with dispersion cup or baffle cup.

GRAIN SIZE ANALYSIS (PIPETTE METHOD)

MODEL: -GT-012 IS 2720 (PART IV) AND BS 1377:2. This is for the determination of the sub sieve particle distribution in a soil sample by mechanical analysis. An analysis of this kind expresses quantity the proportions by weight of the various sizes of particles present in the soil. It is recommended as a standard procedure to use dispersion agent to avoid flocculation. The apparatus consists of a sliding panel which moves up and down by means of a screw allowing Anderson pipette fixed to it to be raised or lowered vertically. A sedimentation tube is held by a laboratory clamp provided on the stand below the pipette. The depth of immersion is measured by a scale graduated in mm at the side of the sliding panel. Supplied complete with Anderson pipette 10ml. At the side capacity made from glass, and a sedimentation tube also of glass of 500ml capacity and 50nos. Test form pads.

ACCESSORIES And SPARES :

i) Sedimentation Pipette (Andersonpipette) 25ml,

ii) Sedimentation tube 100ml,

iii) Sedimentation pipette 10ml,

iv) Sedimentation tube 500ml,

v) Test forms pad of 50

SAND EQUIVALENT TEST SET

MODEL: -GT-013

ASTM D 2419, AASHTO T 176

Used to determine the relevant proportions of clay-like or Plastic fines and dust in

granular soils & fine aggregate Consists of:

1. Acrylic graduated cylinder (4 nos.)

2. Rubber stopper for cylinder (4 nos.)

3. Graduated Steel rule 450 mm

4. Funnel 100 mm plastic

5. Aspirator bottle 5 lts plastic with rubber cock

6. Stand for the aspirator bottle with siphon assembly

7. Irrigation tube with stop pinch cock & weighted foot assembly

MOTORIZED SAND EQUIVALENT SHAKER

MODEL: -GT-014

ASTM D 2419, AASHTO T 176

Sand equivalent tests serve as rapid field-correlation tests to show relative

proportions of clay-like or plastic fines and dusts in granular soils and fine

aggregates. The test separates sand and clay, a comparative reading is

determined between the suspended clay and the settled sand in the measuring

cylinder. Tests may be done in the laboratory or the field. Motorized sand

equivalent shaker features two separate electronic timers (one preset at 45

seconds and the other preset at 10 minutes) to increase accuracy and ease of

operation compared to a spring-type timer. It is recommended for samples in

the laboratory.

The consistent, repeatable oscillation of the apparatus eliminates operator-caused

variation. Shaking operation delivers an 8″ (203mm) stroke at a speed of 175

±2 strokes per minute. Dimensions: 12 x 24 x 24″H (31 x 61 x 61cm).

PROCTOR COMPACTION TEST APPARATUS

MODEL: -GT-016

As Per IS: 2720 (P-VII)

Specification :

Soil compaction is of utmost requirement for constructing earth fill for dams,

canal embankments, reservoirs, highways, runways and railways. The relationship

between soil moisture content and compacted dry density largely determine the

construction specifications and quality control of compacted earthfill. To check the

strength of the soil the density of the soil is taken into account and hence the quality

control is checked otherwise.

SEMI AUTOMATIC COMPACTOR

MODEL: -GT-017

IS 2720 (PART VII and VIII)

Now a days almost every soil laboratory conducts compaction and penetration tests on soils.

In both standard and heavy compaction tests the operator has to count the number of blows

of the rammer on each layer of soil during compaction. A mechanically cum electrically

operated semi-automatic compactor is therefore deviced to eliminate hand compaction process.

Which also considerably saves time with the Rammers provided two stroke lengths, available,

the compactor can be used for normal compaction/heavy compaction as well as C.B.R

compaction.

Specification :

It is a motor driven mechanical compactor useful for soil compaction into 100mm or 150mm

diameter moulds. Two sets of Rammers are provided, one of 2.6 kg and arranged for 310mm

drop and other 4.89kg and arranged for 450mm drop. For compaction soil into 150mm dia

moulds, 100mm face dia Rammers having weight 2.6kg and 4.89kg are used. Where as for

100mm dia moulds they are of 50mm dia. The rammer assembly is provided with a ratchet

and pawl arrangement to lift it from the top of the soil layer. When the rammer ratchet and

pawl arrangement to lift it from the top of the soil layer. When the rammer reaches the

required height the pawl release the rammer which falls freely on soil surface. The release

mechanism is operated by an arm moving up and down which is connected to a reduction

gear coupled to the motor through another arm. An automatic blow counter fitted to the

compactor is used to set the number of blows. The base plate of the specimen mould is to

be fitted to the rotating base plate of the instrument which marks 1/5″ revolution per stroke.

The equipment is suitable for operation on 230 Volts, 50 cycles, Single Phase, A.C. Supply

moulds are to be ordered separately.

UNIVERSAL AUTOMATIC COMPACTOR

MODEL: -GT-018

ASTM D 558, BS 1377-4

It is a motor driven mechanical compactor useful for soil compaction into 100mm to 102 mm

and 150mm to 152.4 mm diameter moulds. Two sets of Rammers are provided, one of 2.5 kg

and arranged for 300 mm and 305 mm drop and other 4.5 kg and arranged for 450 mm and

457 mm drop. The rammer assembly is provided with a ratchet and pawl arrangement to lift

it from the top of the soil layer. When the rammer reaches the required height the pawl release

the rammer which falls freely on soil surface. The release mechanism is operated by an arm

moving up and down which is connected to a reduction gear coupled to the motor through

another arm. An automatic blow counter fitted to the compactor is used to set the number of

blows. The base plate of the specimen mould is to be fitted to the rotating base plate of the

instrument which marks 1/5″ revolution per stroke. The equipment is suitable for operation on

230 V, 50 Cycles, Single Phase, A.C. supply moulds are to be ordered separately.

PROCTOR NEEDLES (SPRING TYPE)

MODEL: -GT-019

ASTM D 1558

The instrument consists of a needle attached to a spring loaded plunger, the stem of

which is calibrated to read 0 to 40 kg division. Long stem is graduated at every 12.5mm

to read depth of penetration and for use with needles of larger areas. The small

penetration stem is also graduation in 12.5mm division and is used with needles of

smaller areas. Needle points one each of 0.25, 0.5, 1.0, 1.5, 2.0, 3.5 and 6.0 sq Cm.

And one tommy pin is supplied. Complete as above in a wooden carrying case.

POCKET PENETROMETER

MODEL: -GT-021

ASTM D 1558 D 2573

This instrument is used to estimate approximate unconfined compressive

strength and the estimation to shear strength of soil Cohesive soils can also

be classified in terms of consistency using this Penetrometer. This is a handy

and convenient instrument.

Specification :

It consists of a light weight barrel assembly with a polished and ground steel

loading piston plunger. A direct reading scale is engraved on the piston barrel

and indicates load in kg. / sq. cm. A maximum load indicator ring is provided

on the penetration plunger. The calibrated spring is heat treated and plated for

rust resistance. The barrel diameter is 20mm and the length 150mm. Supplied

with carrying case.

VICKSBERG PENETROMETER

MODEL: -GT-022

ASTM D 1558 D 2573

This is fork determining the bearing capacity of sub grades or for compaction

control. It also used for rapidly of soils in shallow exploration work.

Specification :

Consists of a study handle under. Which is fixed a sensitive proving ring. An

extension piece is fixed to the bottom of the proving ring and carries a detachable

penetration cone at its tip. Proving ring capacity 100 kg (1kn) and 0.002mm dial

gauge provided indicates the penetration load applied.

SPEEDY MOISTURE METER

MODEL: -GT-023

As Per IS 2720 (P-II), ASTM D 4944 AASHTO T 217

Specification :

Moisture content of soil is generally measured as a ratio of the weight of water

to the weight of solids, expressed in percentage. As soil behavior depends on its

moisture content, it is one of the basic parameters defining the soil condition.

The ‘Moisture’ content of soil, can be obtained quickly with reasonable accuracy

by using a Speedy Moisture Meter. The test technique is based on the fact that

water will react with calcium carbide to form acetylene gas. The quantity of

acetylene gas produced is indicated on a built- in pressure gauge. A conversation

formula gives the corresponding moisture content based on dry weight. Each soil

test equipment is supplied complete in a wooden carrying case consisting of

pressure vessel with clamp for sealing cap, rubber sealing gasket, pressure

gauge in percentage moisture content 0- 25% or 0-50% on the wet weight basis

(6 gm) counter poised balance for weighing samples, scoop for measuring calcium

carbide, bottle of calcium carbide (500gm), a set of 4 steel balls and a cleaning brush.

INFRARED MOISTURE METER

MODEL: -GT-025

ASTM D 4944 AASHTO T 217

This moisture meter has been designed for rapid and accurate determination of

the moisture content of a wide variety of materials. It is torsion wire instruments,

the torque being applied to one end of the wire be means of a calibrated drum to

balance the loss of weight as the test sample dries under infrared radiation. The

speed of drying (about 30 min) thus obtained, combined with the frictionless

balancing system gives the result as accurate as those obtained by standard oven

drying method. Since drying weighing are simultaneous, it is useful specially for

determination of moisture in substances that quickly reabsorbs moisture after drying.

The infrared radiation is controlled by a voltage regulator and thereby provided

excellent heat control. The instrument is provided with an indicator lamp, which

glows when the unit is switched on. The torsion balance has a built-in magnetic

damper or reduce pan vibrations that enables quick weighing. The balance scale

(drum) is divided in terms of moisture percentage on wet weight basis, which are

read directly from it. Graduations are from 0 to 100% in 0.2 % divisions, but

readings may be estimated to 0.1% moisture content. Suitable for operation on 220

V, 50Hz, Single phase, AC Supply.

SAND POURING CYLINDER

MODEL: -GT-026

As Per IS 2720 (P-XXVIII) BS 1377-9

Specification :

The soil testing equipment is used for determination of the dry density of compact,

fine, medium grained soils and for layers not exceeding 50cm thickness. A circular

hole is dug into the ground, all the soil from within it collected, weighed and dried,

and the hole back filled with a standard uniform sand or fine gravel, poured from

a calibrated container for calculating the volume of hole. The complete apparatus

consists of a Sand Pouring Cylinder fitted with Conical funnel and Shutter,

Cylindrical Calibration Container, and a Metal tray with a central hole.

SAND DENSITY CONE APPARATUS

MODEL: -GT-027

ASTM D1556, AASHTO T191

The Sand Density Cone and accessories are used for determination of

the insitu (in-place) density of soils. The apparatus is restricted to tests

in soils containing particles not larger than 2″ (50.8 mm) in diameter.

The Sand Density Cone consists of a double cone assembly with a brass

valve and comes supplied with a one-gallon (4,000 cm3) capacity sand jug.

The Field Density Plates are used in conjunction with the Sand Density

Cones. The center opening of the plate can be used as a template to

control the diameter of the hole and the plate itself is used as a shelf to

prevent the loss of soil during the removal operation.

CORE CUTTER

MODEL: -GT-028

IS 2720 (PART XXIX) 1966 & BS 1377-9

This is used for determination of in situ dry density of natural or compacted

fine grained soil, free from aggregates. A cylindrical cutter is used to extract

a sample of the soil with the help of a dolly and rammer. From the weight,

density and the moisture, and dry density of the soil is ready calculated. It

consists one each of: cylindrical core cutter mode of steel, 127.3mm. Long

and 100mm internal diameter. Steel dolly, 25mm high with a lip to enable it

to be located on top of the core cutter, rammer with detachable steel rod.

SPARE, OPTIONAL EXTRA AND ACCESSORIES:-

1. Cylindrical core cutter 100mm i.d. x 175mm long

2. Dolly

3. Test form pad of 50.

PERMEABILITY-CONSTANT HEAD TEST

MODEL: -GT-028

IS 2720 (PART XXIX) 1966 & BS 1377-9

This is used for determination of in situ dry density of natural or compacted

fine grained soil, free from aggregates. A cylindrical cutter is used to extract

a sample of the soil with the help of a dolly and rammer. From the weight,

density and the moisture, and dry density of the soil is ready calculated. It

consists one each of: cylindrical core cutter mode of steel, 127.3mm. Long

and 100mm internal diameter. Steel dolly, 25mm high with a lip to enable it

to be located on top of the core cutter, rammer with detachable steel rod.

SPARE, OPTIONAL EXTRA AND ACCESSORIES:-

1. Cylindrical core cutter 100mm i.d. x 175mm long

2. Dolly

3. Test form pad of 50.

PERMEABILITY-FALLING HEAD TEST

MODEL: -GT-029

As Per IS 2720 (Part XBII)- 1966 BS 1377; EN DD ENV 1997-2; ASTM D2434; AASHTO T215

This equipment is used for testing the permeability of granular soils

(sands and gravels).The specimen is formed in a permeability cell and

water is passed through it from a constant level tank Take-off points

located along the sides of the permeability cell are connected to three

manometer tubes mounted on a panel complete with a metre scale.

Water passing through the specimen is collected and measured, either

for a specific quantity or over a period of time. The reduction of head

is noted from the variation of water level in the manometer tubes.

Comprising three glass tubes of constant bore, metre scale and

connecting tubing for cell pressure take-off points, all mounted on a

free-standing panel. Manufactured from transparent plastic with

attachment for wall mounting. The inlet, outlet and overflow pipes

are fitted to the base of the tank and can be adjusted for height within

the tank. Supplied complete with connecting tubing.

UNIVERSAL PERMEABILITY

MODEL: -GT-031

As Per IS 2720 (Part XBII)- 1966 BS 1377; EN DD ENV 1997-2; ASTM D2434; AASHTO T215

Clays and silts are tested using the technique. Flow of water through the

specimen is observed by monitoring the rate of fall of water in the tube.

It is essential that soils of very low permeability are sealed inside the

cylinder to prevent seepage along the sides of the specimen. Before testing,

the specimen must be completely saturated with water as the presence of

air will restrict the flow of water. Three glass stand pipes a stand with nine

glass tubes of 6mm, 10mm, 20mm, 25mm, 40mm, 50mm, 60mm, 70mm,

75mm, bore tube is provided with over flow arrangement for constant head

tests. The remaining tubes are used for falling head test.

PYCNOMETER

MODEL: -GT-032

As Per IS 2386 (P-III)

Specification :

Specific Gravity is the ratio of the weight in air of a given volume of a

material at a standard temperature to the weight in air of an equal volume

of distilled water at the same stated temperature. The Pycnometer Bottle

can be used to test a wide range of materials from clay to sand and gravel

smaller than 10mm. It consists of 1kg Glass Jar with Brass Cone, Locking

Ring and Rubber Seal.

SOIL TESTING KIT

MODEL: -GT-033

A very useful kit to determine on the spot soil pH value. This is a

compact kit easy to carry on site.

Consists of :

12 thick walled test tubes with rubber bungs.

1 tube Cleaning brush.

1 bottle of Barium Sulphate (100gm)

1 bottle of Soil indicator (100gm)

1 bottle of Distilled water (500gm)

1 Spatula.

1 Colour chart, range 4.0 to 8.0 ph in 0.5 ph steps.

Complete with carrying case

WATER TESTING KIT

MODEL: -GT-034

I) Acidity Testing Kit

Ii) Chloride Test Kit

Iii) Hardness Test Kit

Iv) Soil Colour Chart

EARTH RESISTIVITY METER

MODEL: -GT-035

ASTM G 57

Capable of measuring earth voltage (V A.C.) 2mA measuring current permits the testing of earth resistance without

tripping earth leakage current circuit breakers in the circuit. Auto power off function. The timer operates auto power

off function. The time operates the “PUSH BUTTON SWITCH” and “TIMER ON BUTTON’ are pressed together.

This will keep the test “NO” for about three to five minutes.

Then auto power off.

Battery operated

Data hold function

Small and light weight

IEC 1010 CAT III 200V

Calibration performed with supplied test leads

Specification:Measurement Ranges

Earth Resistance: 0-20W/0-200W/0-2000W

Earth Voltage: 0-200V AC (40-500Hz)

CONSTANT VOLUME MOULD

MODEL: -GT-036

Often in the laboratories it is required to quickly prepare remoulded

soil specimen for Triaxial and Unconfined tests. Constants volume

moulds are used for this purpose, using either dynamic or static

compaction. The moulds are available in different sizes. For specimen

size 38 mm dia x 76 mm long comprises. Split mould 38 mm dia x 126

mm long. End plugs 38 mm dia x 25 mm long pair. Split collar

interchangeable. Ejecting plunger 38 mm dia x 126 mm long.

Accessories split mould 38 mm dia x 76 mm long and Split mould 38 mm dia x 86 mm long.

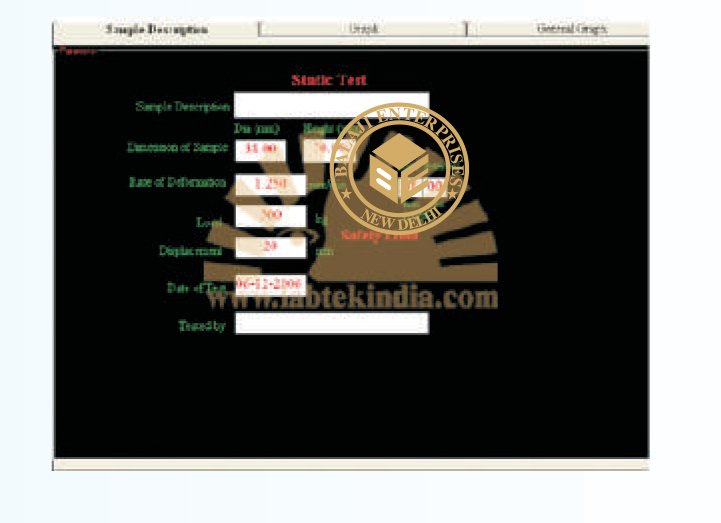

RELATIVE DENSITY TEST

MODEL: -GT-038

IS 2720 (PART XIV), ASTM D 4253 & ASTM D 4254

The equipment is used for the determination of the relative density of

cohesion less free draining soils and meets the essential requirements.

Specification :

The equipment consists one each of: Vibratory table, with a cushioned

steel vibrating decks about 75cm x 75cm. It has a frequency of

approximately 3600 vibratory table, minute under a 11.5kg load.

Amplitude is variable in between 0.65mm in step of 0.05 to 0.25mm,

0.25 to 0.45 mm and 0.45 to 0.65mm. Suitable for operations on 415V,

Three Phase supply. Cylindrical metal unit weight mould, 3000ml.

Capacity.Guide sleeve with clamp assembly. Surcharges base plate for

mould. Handle for surcharge base plate. Surcharge weight. The total

weight together with surcharge base plate and handle is equipment to

140 kg. /sq. cm. For mould. Cylindrical metal unit weight mould 15000

ml. capacity. (Total weight together with the above mould & surcharge

weight is equivalent to 140 kg./sq. cm) dial gauge 0.01mm x 50mm travel.

Extension piece 25mm for dial gauge.

UNIVERSAL EXTRUDES (HYDRAULIC)

MODEL: -GT-039

The extractor frame is used for taking out soil samples compacted or

undisturbed, from 100mm dia and 150mm dia cylinders such as Core

Cutters, Proctor moulds, C.B.R. moulds etc.

Specification:

It consists of a 50Kn capacity hand operated, hydraulic jack mounted

on a suitable frame. Two plungers, one for 4″/100mm dia and the other

of 6″/150mm dia moulds are supplied Height of thrust plate is adjustable.

Set of plungers

SC MODEL TORQUE COMPENSATED POWER PACK

MODEL: -GT-040

ASTM D 698 , BS 598:107

Designed to extract specimens from almost every type of sampling tube and

mould used in solid engineering laboratory or in the field. It can be mounted

vertically or horizontally as desired. It has an unique feature that three 38mm

dia sample.

Specification:

Comprises of a frame designed for screw jack operation, one each of the

adaptors for 38mm, 75mm, 100mm, 150mm dia meter specimens and a stand

to obtain simultaneously three 38mm diameter samples from one 100mm

diameter sample. The adaptor plate which slides along the slotted support can

be claimed at any desired position by means of locking nuts. Besides this, the

tube or mould can be held in position by raising the tube guides and held in

position with locking screws. The lead screw movement can be stopped at any

predetermined position by tightening the lead screw collar. Plunger adaptor

for 200mm dia samples. Adaptor plate with 200mm dia hole and device to

extract b number 38mm dia samples.

SAMPLING TUBES

MODEL: -GT-041

For collection undisturbed samples of 38mm dia for triaxial strength and unconfined compressive strength either

straight from the field or from a sample of larger diameter. The wall thickness is maintained approximately 17 per

cent. Both relieved and unrelieved sampling tubes are available. In the relieved type of tube, the internal diameter

is relieved by about 0.5mm (inside clearance 2%) beyond approx. 19mm length from the cutting edge of the tube.

This is most suitable for highly cohesive soils. In the unrelieved type, the internal diameter is uniform through out.

This type is most suitable for soil of low cohesion. These 38mm dia tubes are available in different lengths.

AUGER POSTHOLE TYPE

MODEL: -GT-042

Augers are used to collect disturbed soil samples at reasonal depths for

laboratory tests. Augers are available in two types and each in different

sizes. Blade type (posthole type) and helical type (screw type). Each auger

outfit consists one each of auger head, one meter long rod, tee piece and

handle. Depth of excavating can be increased using additional extension rods.

Posthole Type:

(a) 50mm, (b) 75mm (c) 100mm dia (d) 150mm dia

Screw Type: (SL-GT-042.A)

(a) 25mm, (b) 38mm, (c) 50mm, (d) 75mm, (e) 100mm, (f) 150mm, (g) 200mm, (h) 250mm, (i) 300mm dia,

Extra: Extension rod 1 meter length with threading at both ends and couplings, set of two spanners and tee piece.

CONSOLIDATION APP. (SINGLE GANG)

MODEL: -GT-043

IS 2720 (Part XV), IS 12287, BS 1377, ASTM D 2435

Consolidation test is un-dimentional test considered extremely important in

soil mechanics. Sample taken from adjacent areas of a single site show

differential settlement even when tested using same techniques. Soil of

similar strength may show varying consolidation. Samples are very carefully

prepared and vertical settlement of the specimen in saturated or drained

conditions carefully recorded when known load is applied.

SPECIFICATION:

The standard outfit comprises of the following items. Loading unit, maximum

capacity 20kg/cm.sq. Having a loading yoke connected to a lever arm with a

counter balancing adjustment and having a lever ratio of 1:1 the whole assembly

being mounted on a sturdy steel frame stand. The loading unit is so designed

that it can be used for consolidation cells of different diameters as well as

different dia floating ring type consolidation cells. Fixed ring type Consolidometer

(Odeometer) cell assembly for testing 60mm dia x 20mm thick specimen comprising:

Fixed ring for specimens 60mm dia x 20mm thick with guide ring. Top and bottom

porous stones for 60mm dia specimen. Perforated pressure pad, Channeled base

with water inlet and gasket Flanged water jacket, water reservoir with plastic tube

and pinch cock. Set of weights to give a pressure of 10kg/cm.sq. On 60mm dia

specimen, comprising : 7 nos. 0.05 kg/cm .sq., 5nos. 0.1 kg/sq.cm., 6nos. 0.5kg/sq.

cm., and 5 nos. 1.0 kg/sq.cm. Supplied complete as above but without dial gauge.

ACCESSORIES :

Dial gauge 0.002 mm x 10mm. Extension piece, 40 mm long, consolidation test

forms pad of 50 for one dimensional consolidation.

OPTIONAL EXTRAS :

Varying head stand pipe, 50cms. Long with mm. Scale. Fixed ring type of

Consolidometer (Odeometer) cell assembly for 50mm. dia x 20mm thick specimens ,

complete with fixed ring guide ring. Pair of porous stones, perforated pressure pad,

channeled base, gasket and flanged water jacket. Set of weights to give a pressure

of 10kg/sq.cm. on 50cm. dia specimen. Fixed ring type of Consolidometer (Odeometer)

cell assembly for 70mm dia x 20mm thick specimens, complete with accessories as above.

Set of weights to give a pressure of 10 kg/sq.cm. on 70mm dia specimens. Fixed ring

type of consolidometer (odeometer) cell assembly for 100mm dia x 25mm thick specimens,

complete with accessories as above. Set of weights to give a pressure of 10 kg/sq.cm. on

100mm. Dia specimens.

CONSOLIDATION APP. (THREE GANG)

MODEL: -GT-045

IS 2720 (Part XV), IS 12287, BS 1377, ASTM D 2435

Rigidly manufactured from aluminous alloy casting to provide a high

degree of accuracy with any frame distortions under load. The load bridge

group is supported in high accuracy self-aligning seat balls. The beam

provides three loading ratio: 9:1 10:1 11:1 and the beam assembly is

fitted with an adjustable counterbalance weight. It consists of 3

consolidation test assemblies mounted on a single frame. Complete

with 3 sets of Consolidation cell assembly for 60mm dia samples and

three sets of weights each giving 10 kg/sq.cm. On each sample. And

complete with rod holding the weights and coupling block holding the

dial gauge or transducer. Supplied ‘without’: Consolidation cell, Weights,

Dial Gauge (or transducer), holding bench which have to be ordered

separately.

SOIL TRIMMER (HAND OPERATED)

MODEL: -GT-048

ASTM D 698 , BS 598:107

For trimming various diameter specimen for triaxial and unconfined c

ompression tests.

Specification:

The lower specimen grip is mounted on a disc which rotates freely.

The soil sample is mounted on the lower specimen grip and the upper

grip is firmly seated on top of the specimen. The vertical guide can be

adjusted to control the depth of cut. While trimming the lower disc is

rotated by hand. Supplied complete with a wire saw. Trimming knife,

mounted on a support, can be adjusted horizontally as well as vertically

to permit trimming of the specimen to the exact size of the ring. A guide

supplied prevents over cutting. Complete with 38mm, 50mm, 75mm and

100mm dia specimen rings.

SOIL LATHE BENCH MOUNTING

MODEL: -GT-049

This instrument is used for preparing soil samples for various tests like

Triaxial Test, Unconfined Compression Test etc. Soil lathe consist of a

cabinet enclosing motor and gear system which rotates a disk at 24 R.P.M.

this disc adopts gripper plate of various size. An up right has an adjustable

holder and takes upper gripper plates of different diameters. Arrangement

is provided to control height and depth of cutting tool through a lead screw

which has speeds 0.8mm/min. And 1.6mm/min. Supplied complete with

gripper plate pairs for 38mm, 50mm, 75mm, and 100mm dia specimens.

DIRECT SHEAR APPARATUS (MANUALLY)

MODEL: -GT-050

Information of Shear values plays an important role the design of sub-structures in determining bearing capacity of

soils, design of retaining walls, instability calculation earth slopes etc. Various Shear Apparatus are available and

Direct Shear Apparatus is one of them. In Direct Shear test specimen contained in a box is subjected to a constant

normal load and increasing horizontal load is applied to the upper section of the specimen. Shear force and load are

directly measured.

AS PER IS: 2720 (Part-VIII), ASTM D-3080

For determination of the direct shear strength of soils on specimen size 60 mm x 60 mm x 25 mm.

Specification: The apparatus comprises of the following:

Loading Unit:

Supplied with load yoke with direct and lever system for applying load.

Normal stress capacity 8kg/sq.cm. Load is applied either directly of

through a counter balanced detachable lever. Provision is made for

load to be applied either through a steel ball recessed in the loading

pad or direct through a boss on the pre calibrated loading yoke. The

loading unit is provided with V strips and roller strips for frictionless

movement of shear box housing.

Shear Box Assembly:

Comprising Direct Shear box in two halves for a square specimen

size 60 x 60 x 25 mm one pair of plain gripper plates, one pair or

perforated gripper plates, one pair or porous stones, one top loading

pad. Shear box housing: Accommodates the Direct Shear Box assembly.

Complete with two ball roller strips.

Specimen Cutter:

For cutting 60 x 60 x 25 mm specimen from larger samples. Set of weights

to give a normal stress of 3 kg/sq.cm.

through lever as follows:

To give kg/cm sq. – Qty.

0.05 – 4 Nos.

0.1 – 1No.

0.2 – 1No.

0.5 – 3Nos.

1..0 – 1No.

Complete set as above but without proving ring.

Nett weight 140Kg.

Essential Accessories:

High sensitivity compression ring cap 200 kg one consolidation dial gauge 0.01 mm x 25 mm and one strain dial gauge

0.01 mm x 25 mm and one strain dial gauge 0.01 mm x 25 mm.

Optional extras:

Additional set of weights to give a normal stress of 5 kg/cm2 Soil Sampler for 60 mm x 60mm specimen and test from

pad of 50. Spares:

Porous stone for 60 mm x 60 mm size sample available in pairs

CBR APPARATUS MANUALLY OPERATED

MODEL: SL-GT-055

As Per IS 2720 Part (XXXIX) ASTM D-3080, Bs1370

An automatic system enables performing of Direct Shear and Residual

Shear tests through a total computer control. It is a tablemounted model

and has stepper motors controlling shearing load. Stress levels can be

maintained with in the limits of +0.5% through set of weights. Vertical

and horizontal displacements and shearing load are all displayed in their

respective engineering units on LCD display. Board specification of the

unit are:- RS 232 output for connection to PC, Display of both speed and

displacement with 0.0000 mm resolution, Shear speed between 0.00001 to

9.99999 mm/minute

Max shear effort:

5000 N possible on the whole speed range Possibility of direct vertical load,

or with a lever arm ratio 10:1

Max vertical direct load:

500N; with lever arm: 5500N Display and pilot lamps to signal any bad functioning and alarms Box group mounted on

ball track with high qualit antifriction system Read value results are immediate and of extreme accuracy Extremely easy

and practical use, not requiring qualified staff. Shear box, hollow punch and tamper are not included in the standard

supply and have to be ordered separately Power supply: 230 V A.C. Single Phase 50Hz

DIGITAL DIRECT SHEAR TEST APPARATUS

MODEL: SL-GT-055

As Per IS 2720 Part (XXXIX) ASTM D-3080, Bs1370

An automatic system enables performing of Direct Shear and Residual

Shear tests through a total computer control. It is a tablemounted model

and has stepper motors controlling shearing load. Stress levels can be

maintained with in the limits of +0.5% through set of weights. Vertical

and horizontal displacements and shearing load are all displayed in their

respective engineering units on LCD display. Board specification of the

unit are:- RS 232 output for connection to PC, Display of both speed and

displacement with 0.0000 mm resolution, Shear speed between 0.00001 to

9.99999 mm/minute

Max shear effort:

5000 N possible on the whole speed range Possibility of direct vertical load,

or with a lever arm ratio 10:1

Max vertical direct load:

500N; with lever arm: 5500N Display and pilot lamps to signal any bad functioning and alarms Box group mounted on

ball track with high qualit antifriction system Read value results are immediate and of extreme accuracy Extremely easy

and practical use, not requiring qualified staff. Shear box, hollow punch and tamper are not included in the standard

supply and have to be ordered separately Power supply: 230 V A.C. Single Phase 50Hz

CBR APPARATUS MANUALLY OPERATED

MODEL: -GT-056

California Bearing Ratio Test (CBR)

The C.B.R. Method is used for finding the relative bearing ratio and

expansion characteristics of soil of base, sub-base and sub-grade for

the design of roads, pavements and runways.

Test can be made on all types of soils including sand, gravel, crushed

stone etc. (Passing through 20mm IS sieve) C.B.R. test is used extensively

for selection of materials and control of sub-grades. The procedure of test

is very simple. A 50mm dia. penetration piston is forced in the test soil

and loads required for the penetration to penetrate different depths are

recorded by means of a proving ring fixed to the penetration piston assembly

and a dial gauge. Both Laboratory C.B.R and field C.B.R apparatus are available.

AS PER IS: 2270 (PART-XVI)

California Bearing Ratio Apparatus is made both for laboratory and field use. CBR test is to evaluate the bearing capacity

of soil for the flexible pavement design. It is extensively used for the selection of mater ials and cont rol of subgrades. The

potent ial expansion/consolidation of the specimen is also measured before each test, under known surcharge weights.

This apparatus comprises of :

A hand operated load frame 50kN capacity, A mould of 150 mm. I.D. x 175 mm. high with clamping lugs complete with

extension collar and perforated base plate made of gun metal. A cutting collar to fit mould body. A penetration piston

assembly of 50 mm. diameter and a bracket for the dial gauge. A perforated swell plate of 148 mm. diameter with an

adjustable stem and lock nut. A circular spacing disc of 148 mm. diameter x 47.7 mm. high complete with a removable

`T’ handle. A metal tripod for the dial gauge.

Surcharge weight :

annular _ 2.5 kg., 147 mm. diameter. Surcharge weight : slotted _ 2.5 kg., 147 mm. diameter.

CBR ACCESSORIES

MODEL: -GT-056

CBR Essential :

– Proving ring 10 kN capacity.

– Dial gauge 0.01 mm. x 25 mm. travel.

Spares:

– Rammer 2.6 kg & 4.89 kg.

– CBR mould complete with extension collar and perforated base plate

– Perforated swell plate with adjustable stem and lock nut

– Solid base plate

– Cutting collar

– Penetration piston assembly

– Metal tripod for dial gauge

– Circular spacer disc

– Surcharge weight (Annular) 2.5 kg

– Surcharge weight (Slotted) 2.5 kg

CBR TEST APPARATUS MOTORIZED

MODEL: -GT-057

IS : 9669, IS : 2720 (Part XVI)

It is used in large road construction projects has increased considerably

in recent years. This apparatus, mounted on a rolled steel joint cantilevered

from the back of the truck or fitted to the underside of a mobile frame, can

be used to determine the bearing capacity of soils quickly and efficiency.

This method of testing in-situ, using piston penetration, is useful for

determining the load carrying capacity in the field, when the in -place density

and water contents are such that the degree of saturation is 80% or greater.

When the material is coarse grained and cohesionless so that it is not affected

b changes in the water content and when the material has been inplace. Similar

to above but supplied with bench mounting type 5000kgf. Capacity load frame

motorized, in place of load frame hand operated. The lead screw of the load

frame has a single constant rate of travel of 1.25mm/minute.

Dial Gauge 2 in. travel & 0.001 in division for CBR penetration measurement,

having provision for increasing the dial gaugeplunger length .Proving ring ,

50 kN (5,000kgf) capacity x 0.5. kN/Div sensitivity/ readability, one with 25 kN capacity x 0.04 kN / div sensitivity /

readability and one with 10 kN capacity x 0.01 kN / div sensitivity / readability.

Note: Proving Rings of other capacities are also available.

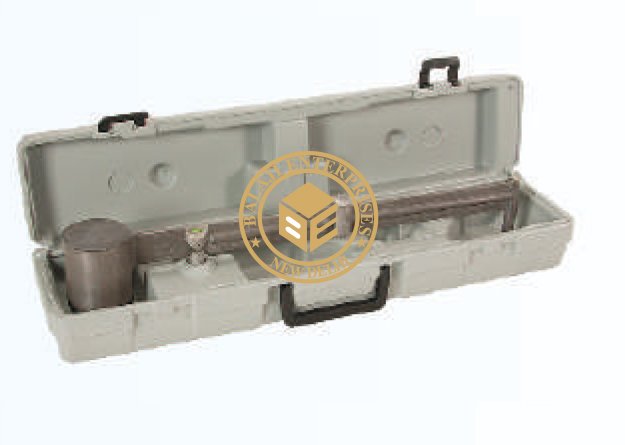

CBR TEST APPARATUS (FIELD TYPE)

MODEL: -GT-058

IS 2720 (PART XXXI) 1969.

In recent years it has become important to know C.B.R. values in situ.

It is useful in determining the load carrying capacity in the field when

in place density and water contents are such that the degree of saturation

is 80% of greater, when material is cohesionless and coarse grained, such

that it is not effective by changes in water contents and when the material

has been in place for considerable the loading is effected by means of a

mechanical load frames which can be fixed to the under side of a truck.

Specification:

Mechanical screw loading jack, 10,000 kg. Capacity with u-bracket and swivel head. Penetration piston, 50mm dia.

Threaded at the upper end. Extension rods consisting of 2 lengths 5 cm. g lengths 10cm. 1 length 30 cm., 1 length 50 cm.

and 1 length 100 cm. used as spacers between the proving ring and penetration piston. The lengths are machined from

steel tubing. Connector set, has eight connectors for coupling the penetration piston and proving ring assembly either

directly or through extension pieces. Dial gauge support of seamless pipe constructions. It stands 30 cm high and 45 cm.

Wide at the base. Provided with a quick release screw type clamp capable of sliding and locking anywhere along 2 meter

length of the bridge. Supplied with annular metal weight 5 kg., 250mm dia with 53 mm dia central hole, slotted metal

weight 5 kg., 215mm to 250mm dia with 53 dia slot 2 nos.

SWELL TEST APPARATUS

MODEL: -GT-059

It is designed to determine the swelling pressure developed by soil

specimens moulded to desired densities at known moisture contents,

when soaked in water. The load applied to restrain the swelling is

transferred on to a load measuring proving ring through a perforated

swell plate and a load transfer bar. The proving ring is attached to

the lead screw of hand operated load frame. A soaking tank is provided

for saturating the specimen and the base of the mould provided has

channels and radial grooves with connecting holes.

Load Frame, Hand Operated, Capacity 50 KN (5,000 kgf), Mould,

100mm dia x 127.3mm height (1,000ml volume) with, base plate and

collar., Proving Ring, with integral boss, high sensitivity 2.5KN (250 Kgf) capacity, Perforated swell plate, 100mm dia

x 16mm thickDial Gauge , 25mm travel, 0.01mm least count Lid & receiver in G.I. frame for 300mm dia x 450mm dia

sieves, Spencer, 100mm dia x 12.7mm thick, Pair of Porous stones, 100mm dia x 12.7mm thick, Load Transfer Bar,

Steel Ball Soaking Tank, 250mm dia x 210mm high.

UNCONFINED COMPRESSION TESTER PROVING RING TYPE (HAND OPERATED)

MODEL: -GT-059

It is designed to determine the swelling pressure developed by soil

specimens moulded to desired densities at known moisture contents,

when soaked in water. The load applied to restrain the swelling is

transferred on to a load measuring proving ring through a perforated

swell plate and a load transfer bar. The proving ring is attached to

the lead screw of hand operated load frame. A soaking tank is provided

for saturating the specimen and the base of the mould provided has

channels and radial grooves with connecting holes.

Load Frame, Hand Operated, Capacity 50 KN (5,000 kgf), Mould,

100mm dia x 127.3mm height (1,000ml volume) with, base plate and

collar., Proving Ring, with integral boss, high sensitivity 2.5KN (250

Kgf) capacity, Perforated swell plate, 100mm dia x 16mm thickDial

Gauge , 25mm travel, 0.01mm least count Lid & receiver in G.I. frame

for 300mm dia x 450mm dia sieves, Spencer, 100mm dia x 12.7mm thick,

Pair of Porous stones, 100mm dia x 12.7mm thick, Load Transfer Bar,

Steel Ball Soaking Tank, 250mm dia x 210mm high.

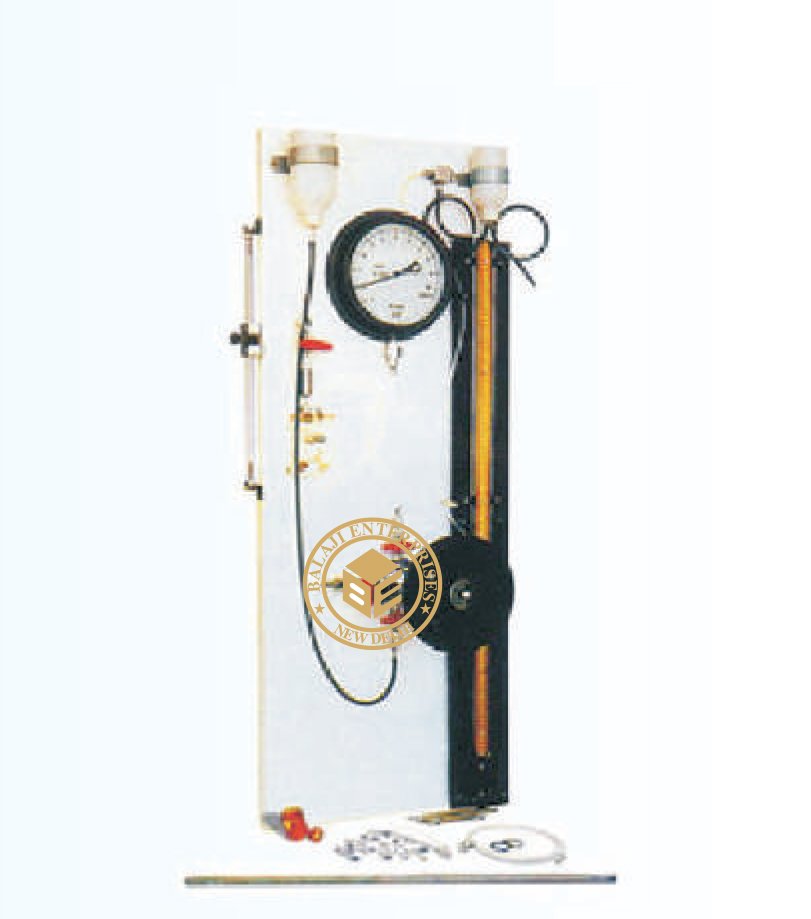

PORE PRESSURE APPARATUS 10KG/CM2

MODEL: -GT-062

This apparatus is used for measuring pore water pressure and pore air

pressure in soils. This is as per the principals outlined in the book

” measurement of soil properties in triaxial tests” by A.W. BISHOP

and D.J. HENKEL. This is used as an accessories for triaxial test apparatus.

SPECIFICATION :

The apparatus consists of a panel for wall mounting on which are fitted

1.0 to 10kg/cm sq x 0.1kg cm. sq. a pressure gauge, bourdon tube type

15 cm dia.

MANOMETER :

Glass u-tube manometer for measuring low positive pore pressures negative

pore measures and checking zero error of pressure gauge. It is provided

with a mercury trap (mercury supplied at extra cost.) Null indicator made

out of clear transparent Perspex with mercury trap and cursor to indicate

the mercury level.

BURETTE :

50ml burette for measuring the volume change in the soil specimen. Pressure pump fitted with four sleeve packed valves,

operated by means of a hand wheel on the end of the piston rod which is threaded through the pump cap and gives a

smooth, fine adjustment of pressure. Copper coil and water reservoir is fitted on board with complete stand assembly.

The unit is tested against leaks up to 10kg/cm sq.

DEAD WEIGHT TYPE OIL AND WATER CONSTANT PRESSURE SYSTEM

MODEL: -GT-064

BS 812 This device is used to maintain cell pressure constant for a long

duration and the system can be used in place of conventional constant

pressure system using mercury pots where certain minimum heights are

required. Problems like de-airation of pump, leakage of mercury etc. is

eliminated in this system . This unit is smaller in volume and can be used

in mobile laboratory also. This can maintain pressure in the cell upto

20kg/cm sq. Pressure is maintained constant in the system by a balancing

calibrated weights on a spindle against a column of oil, operating under

constant feed back.

CONSTRUCTION :

The system consists of an oil pump continuously driven by an electric motor

during the test period. The internal components are housed in a strong compact

housing. The piston on which weights are kept rotates with minimum friction.

A transparent oil water vessel is provided to transmit pressure to the cell. A hand pump provided facilitates priming

and to maintain constant pressure during power failure.

SPECIFICATION :

Range 0-20 bar(0-20kg/cm2 ), Steps of pressure 0.5bar (0.5kg/cm2 ), Accuracy + 0.5%, Electric supply 230 V,

Single Phase, 50 Hz, A.C. supply., Supplied complete with pressure gauge, flow valves, connecting pressure,

hose and set of weights to give maximum pressure of 20 bar (20 kg/cm2)

LOAD FRAME HAND OPERATED

MODEL: -GT-065

Triaxial Setup

Triaxial setup has different main components. These components are

selected to complete the setup. In the following pages specifications are

given of each components. Main component requirement for this test are:

I) Load Frame

ii) Triaxial Cell

iii) Lateral Pressure Assembly

iv) Measuring Unit

Load Frames

Load frame is essential equipment for carrying out Unconfined Compression,

CBR and Triaxial Shear Tests. Since very slow rates of strains are required

for Triaxial Shear Tests LabTek load frame are made to suit the same.

A suitable frame can be selected from a wide range of LabTek series of Load frames depending upon the type of test

and the size of sample. Each load frame is provided with a standard proving ring adaptor having ½” BSF male threads

to suit LabTek range.

Load Frame, Hand operated, 50 kN

The load frame is designed for a maximum load of 5000 kgf. It consists of a screw jack mounted in a reversible

channel frame, which can be used for loading from top to bottom and vice versa

LOAD FRAME, MOTORIZED, 50 KN (1 SPEED)

MODEL: -GT-066

Triaxial Setup

Triaxial setup has different main components. These components

are selected to complete the setup. In the following pages specifications

are given of each components. Main component requirement for this test are:

I) Load Frame

ii) Triaxial Cell

iii) Lateral Pressure Assembly

iv) Measuring Unit

Load Frames

Load frame is essential equipment for carrying out Unconfined Compression,

CBR and Triaxial Shear Tests. Since very slow rates of strains are required

for Triaxial Shear Tests LabTek load frame are made to suit the same.

A suitable frame can be selected from a wide range of LabTek series of Load

frames depending upon the type of test and the size of sample. Each load frame

is provided with a standard proving ring adaptor having ½” BSF male threads

to suit LabTek range.

Load Frame, Motorized, 50 kN (1 Speed)

It is a single speed load frame designed for 1.25 mm/min strain rate. It

can accommodate Triaxial cells up to 100mm diameter specimen.

Loading capacity is 50kN.Operates on 220V,50Hz supply

DIGITAL LOAD FRAME

MODEL: -GT-070

It is an advanced version of mechanical load frames. In this load

frame, rate of strain is controlled through combination of

electronics and micro stepper motor. The unit operates on 220Volts

50Hz single phase supply.

TRIAXIAL CELLS

MODEL: -GT-071

IS 2720 (PART XII)

The cell is useful for testing 38mm dia x 76mm high soil specimen.

Transparent Perspex chamber with anvil and loading plunger, the

cell is easily opened by releasing four nuts of the tie rods. It is leak

proof up to 10kg/cm.sq. Fluid pressure. An oil plug which can also

be used as an air vent is provided for introducing a thin layer of oil

over water. This provides effective sealing at the plunger for long

duration tests. The cell is fitted with four sleeve packed valves of no

volume change type on the base.

These valves are used for cell pressure, pore water pressure, drainage

or back pressure. The loading plunger of the cell has dial gauge rest.

Loading pad made of Perspex for 38mm dia specimens. Pair of plain

discs made of Perspex 38mm dia 6mm thick. Pair of porous stones

38mm dia specimen. Split sand former for 38mm dia specimen. Sheath

stretcher for 38mm dia specimen. One dozen rubber sheaths for 38mm

dia samples. For synthetic rubber ‘o’ rings for 38mm dia specimen.

One plastic drainage tube.

LATERAL PRESSURE ASSEMBLY

Lateral Pressure Assembly 10kg/cm2

It is designed for application of cell pressure upto 10kg/cm on a triaxial

specimen in the triaxial cell. The unit is mostly used in routine tests which

last for about 10 to 15 minutes wherein the variations of cell pressure can

be tolerated.

Specification:

The apparatus consists of a pressure chamber which has a flanged top 2

cap fitted with a 10 kg/cm . Pressure gauge and a valve for pumping in air.

Water inlet and drain cock are fitted to the chamber. 2 The foot pump

supplied easily develops a pressure of 10 kg/cm2 Complete with connecting

pressure hose.

Lateral Pressure Assembly 20kg/cm2

Same as above but suitable to develop pressure upto 20kg/cm fitted with suitable pressure gauge.

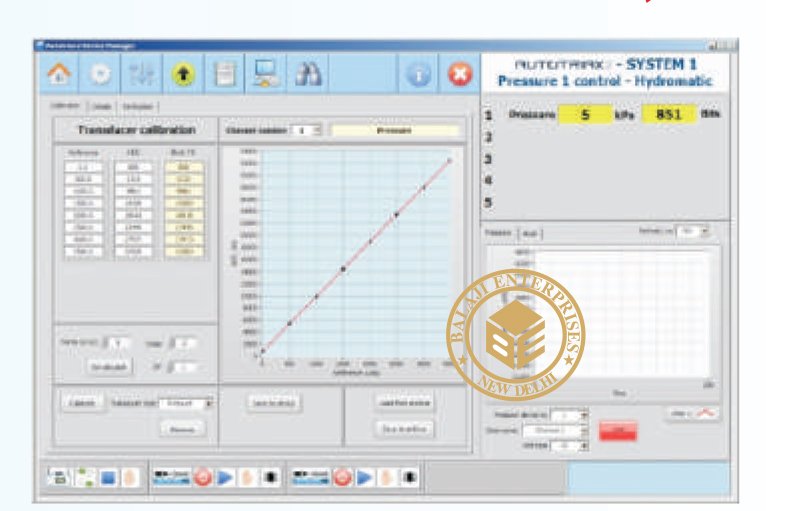

DIGITAL TRIAXIAL SHEAR TEST APPARATUS

MODEL: -GT-072

IS-2720 (Part-XII) and BS-1377.

LabTek Digital Triaxal is totally automated stress path system for soils and conforms to the test requirements of All the

modules namely load frame, confining pressure, back pressure, pore pressure or volume change are totally controlled by

the dedicated computer. Once the specimen is assembled in the triaxial cell, required parameters like strain rate,

confining pressure and back pressure are programmed through the computer. Controlling and data acquisition is

supported by window based software. It can perform tests under the following conditions:

1. Shear in UC, UU, CU, CU & CD

2. Stress path triaxial test

3. K0 consolidation and swelling test (optional) Detailed

specifications of the individual modules are given as under:

1. Load Frame

It is a two-pillar type load frame that can accommodate triaxial

cell up to 100mm dia specimen. Rate of strain is precisely controlled

through micro stepper motor of fractional horsepower operating at

220volts, 50 Hz single phase supply (other voltages optional).

i) Capacity of the load frame : 50 kN

ii) Rate of strain: 0.00001 – 9.9999 mm/min

iii) Travel : 100 mm Limit switches and L.E.D are incorporated in the

hardware to arrest the travel limits and also to indicate the direction of movement (up/down).

2. Triaxial Cells

Selection could be made from wide range of triaxial cells, they are light weight cells. Transfer bar (loading ram) passes

through linear bearing making it almost friction free. Base has four no-volume change valves one each for back pressure/

pore pressure, confining pressure and top drainage.

Specimen size : 38/50mm diameter

Accessories: As standard the following accessories are supplied along with the

Triaxial Cell: -Sheath Stretcher, Porous Stones, Plain Discs, Top drainage Cap, Rubber membranes (Pack of 10) and

‘O’- Rings.

(Universal Triaxial cells)

Confining Pressure : 1700 kPa

Specimen size:

38 mm dia x 76 mm high, 50 mm dia x 100 mm high, 75 mm dia x 150 mm high, 100 mm dia x 200 mm high

Standard accessories include, Sheath Stretchers, Rubber membranes (Pack of 10), ‘O’- Rings, Porous stones,

plain discs and top caps.

3. Pressure Controller For Confining Pressure

A micro stepper motor runs pressure controller and the controlling is done through computer. Sensitivity of controlling

is within +10 kPa. Volume displacement in one filling is approximately 300 c.c. Sensing of pressure is through sensitive

pressure sensor.

Pressure range : 1700 kPa

Volume capacity : 300 cc

Controlling accuracy : +10 kPa

4. Pressure Controller For Back Pressure with volume change

Pressure range : 1700 kPa

Volume : 300 cc

Sensitivity : +10 kPa

Volume change

Measurement : 300*0.01cc

5. Sensors

Force Sensor Load cell capacity: 10kN

Pressure Sensor Range : 2000 kPa

Displacement Sensor Range : + 20mm

6. Computer

Pentium IV – 3.0Ghz or higher 512MB RAM, 80 GB HDD, CD writer, Standard Keyboard , Scroll Mouse,

Color Monitor, Deskjet/ Laser Printer (if requred)

Note : Up graded system will be supplied.

SOFTWARE FOR TRIAXIAL TEST (ALL ELECTRONIC MODELS)

1). Does all calculations of UC, UU, CU,CU & CD triaxial tests

2). Has option for manual as well as automatic recording of data

3). Displays the following plots (Graphical)

a). Plots consolidation curve & evaluates t100 and calculates strain rate

depending Upon the drainage condition in CD & CU

b). Stress – strain curves after every test

c). Plots pore water pressure and A – factor (for CU) and volumetric strain

(for CD) vs. axia Effective stress ratio vs. axial strain

d). p-q plot

e). Mohr stress circles & envelope giving C & in terms of effective stress.

SOFTWARE FOR TRIAXIAL TEST (ALL ELECTRONIC MODELS)

1). Does all calculations of UC, UU, CU,CU & CD triaxial tests

2). Has option for manual as well as automatic recording of data

3). Displays the following plots (Graphical)

a). Plots consolidation curve & evaluates t100 and calculates strain rate

depending Upon the drainage condition in CD & CU

b). Stress – strain curves after every test

c). Plots pore water pressure and A – factor (for CU) and volumetric strain

(for CD) vs. axia Effective stress ratio vs. axial strain

d). p-q plot

e). Mohr stress circles & envelope giving C & in terms of effective stress.

DIGITAL TRIAXIAL ACCESSORES

OPTIONAL ACCESSORIES.

1 Lateral extensometer (submersible type).It is a ring type extensometer

which exerts a bare nominal pressure on the specimen. Extension/

contraction is measured by submersible L.V.D.T and the parameter

is directly displayed on the monitor in engineering units. *

STATIC CONE PENETROMETER CAPACITY 100KN (10,000KGF) (ENGINE DRIVEN)

MODEL: BE-GT-074

IS 4968 (PART III)

For reaching greater depths and to facilitate easy and constant rate of penetration 1 to 2.5cm/sec of the cone this

engine-driven Static Cone Penetrometer of 100 KN (10,000 Kgf) capacity is preferable. The equipment consists of a

hydraulic pump driven by a Diesel Engine. The whole system is mounted on a tow able trolley fitted with pneumatic

wheels. The pumping unit and ram are connected by means of flexible pipes through a direction control valve. The

hydraulic ram moves on a two pillar stand mounted on a trolley.

Complete With The Following :

01). Penetration Cone, steel 60 cone angle, 10cm2 base area, with friction jacket One

02). Mantle Tube, 36mm uniform OD with sounding Rod working length 1 m Thirty

03). Load Measuring Head, with Automatic cut-off valve, and oil can without pressure gauges. One

04). Pressure Gauge, 0-600 x 5 kg/cm One

05). Pressure Gauge, 0 100 x 1kg/cm One

06). Trusses Two

07). Screw Anchor 45 cm Six

08). Screw Anchor 30 cm Six

09). Screw Anchor 20 cm Six

10). Screw Anchor Rod with cone Six

11). Driving handle for Screw Anchor One

12). Extension Pipe for Handle Four

13). Clamping Screw with Nuts Six

14). Extractor Tube with Connector One

15). Tarpaulin Cover One

STATIC CONE PENETROMETER, 30KN (300KGF) CAPACITY, HAND OPERATED

MODEL: -GT-073

IS 4968 (Part III)

Static cone penetration test is internationally recognized as a standard field test to collect data about bearing capacity and

frictional resistance of soil.Static C one Test is unsatiable e for gravelly soils. The Static Cone resistance is correlated with

the ‘N’ value as obtained from standard penetration test, thus in cr easing the utility of the test.

The drive is by means of a rack and pinion manually through a gearing arrangement.

The gear box and pinion are fixed on two handles, sprockets and chain arrangement.

The movement of the rack is guided by a bracket ( attached to the rack) and two pillars.

The penetration resistance i.e. the pressure is indicated on hydraulic gauges through a

hydraulic measuring head. Two pressure gauges of 15cm dia dial and 2 capacities

0-160kg/cm are provided. An automatic cut-off valve, to protect the low capacity gauge

from being overloaded is provided. The 2 valve can be adjusted and locked at desirable

values between 20 to 60cm . A provision is made to anchor the unit to the ground (with

the help of four anchors supplied with the unit) and there is a provision for lateral 2

movement of the unit so that subsequent tests could be performed without shifting the

entire anchorage. A 10cm penetration cone with friction jacket is provided along with

fifteen mantle tubes (non-uniform having an effective length of 1 m each with sounding

rods for finding out the cone (point) resistance or jacket friction.

It consists of :

01) Penetration Cone, steel 60 angle 10cm base area with friction jacket One

02) Mantle Tube, non-uniform , 36mm OD at the two ends and reduced dia in between with sounding rod working

length 1mfifteen.

03) Load Measuring Head, with Automatic Cut off valve and Oil Can, without Pressure Gauge One

04) Pressure Gauge, 0-60kg/cm One

05) 2 Pressure Gauge, 0-160kg/cm One

06) Screw Anchor , with Bolt Four

07) Anchor Driving Handle One

08) T-Rod One

09) Spanner One

10) Extension Pipe 0.5m long for Anchor Driving Handle Four

Note : Uniform dia mantle tubes can be ordered at extra cost.

Optional Extra

Mantle Tube, 36mm uniform OD with Sounding Rod, working length 1 m

SPLIT SPOON SAMPLER

MODEL: -GT-075

IS 2131-1963, IS 9640-1980

This is used for standard penetration test for determining penetration resistance (N valve) of soil which can be related to

unconfined compressive strength. Penetration resistance (N value) of soil is determined by giving a number of blows with

a 65 kgs weight falling through a given distance of 75cm required to penetrate the assembly to a depth of 30 cm when

properly seated on the ground. The sampler is made from a steel tube split length wise & held together by a head fitted

with a ball check valve & a hardened steel shoe in size cutting edge of 35mm dia. The sampler is 35mm i.d. & 50.8mm in

outer dia & 508mm long. One adopter to connect ‘A’ type drill rods is also supplied.

Spares :

Body of split spoon sampler, shoe of split spoon sampler,

head of split spoon sampler.

STANDARD PENETRATION TEST SET

MODEL: -GT-076

IS 2131, IS 9640

This can be used in drilling operations to increase the footage & improve

jab safety consist of three metal pipe legs approximately 5 mtr. long

connected by a tie bolt each leg is made up of two parts for ease of

transportation complete with one pulley one leg has building ladder

Standard Penetration Test is a powerful tool for measuring the penetration

resistance of the ground and for relating it to the degree of compactness of

cohesionless soil and consistency of cohesive soil. The results can be used for

design of foundations. SPT is widely used for measuring the undisturbed

strength of the soil and for assessing its resistance to liquefaction due to

ground vibrations caused by earthquakes or other dynamic forces. The

Standard Penetration Resistance is measured as the number of blows ‘N’

required to drive a split spoon sampler to a depth of 300 mm using a 65 kg

weight falling freely through a height of 750 mm.

DROP HAMMER AND GUIDE PIPE

MODEL: -GT-078

For determining the resistance of different types of soil strata to dynamic

penetration of a 50 mm cone and thereby obtain an indication regarding

their relative strength or density or both. The method helps reconnaissance

survey of large area in a short time. Weight 65 Kg. Complete with two end

caps to give a free fall of 75cm the drop hammer

DYNAMIC CONE PENETRATION TEST

MODEL: -GT-079

The Dynamic Cone Penetrometer (DCP) is used for rapid in-situ measurement

of the structural properties of exsisting road pavement constructed with

unbound materials.The unit incorporates an 8 kg weight having a drop of 575

mm, fitted to the end of the shaft is a 20 mm diameter cone. With the standard

DCP measurements can be made down to a depth of approximately 850 mm.

Readings are usually taken after a set number of blows, changing the number

according to the strength of the layer being penetrated. For good granular

bases, readings every 5 – 10 blows are satisfactory, but for weaker sub-base

layers and subgrades, readings every 1 – 2 blows may be appropriate The DCP

requires three operators, one to hold the instrument in a vertical position, one

to raise the hammer and let it fall and one to record the results. A typical test

takes only a few minutes, providing a very efficient method of obtaining information which would otherwise require the

excavation of test pits. Where pavement layers have different strengths, boundaries can be identified and layer thickness

determined

LABORATORY VANE SHEAR APPARATUS

MODEL: -GT-080

IS 2720 (XXX)-1968 BS 1377.

Consists of a torque head adjustable in height by means of a lead screw rotated

by a drive wheel to enable the vane to be lowered into the specimen. Rotation of

the vane is by means of a hand wheel which operates a worm gear arrangement

turning the upper end of a calibration torsion spring, vane dia, rod dia, vane size

& vane height are as per IS specifications. The vane shaft is attached through the

hollow upper shaft to a resettable pointer, which indicates the angle indicates the

angle of torque on a dial graduated in degree the dial reading multiplied by spring

factor gives the torque a container for soil sample is also supplied & a sampling

tube of 38mm. i.d. & 150mm long can also be used as container . Supplied with

set of four springs, one each of approx. 2 kgs/cm sq., 4kgs/cm sq., 6 kgs/cm sq.

& 8kgs/cm sq. complete as above in a wooden carrying case

IN-SITU VANE SHEAR TEST APPARATUS

MODEL: -GT-082

IS 4434

This apparatus is designed for conducting in-situ Vane hear test from

the bottom of bore hole in saturated cohesive deposits, for determining

their in-place shearing resistance.The equipment consists of a torque

applicator assembly mounted on a base. A gear wheel, which is marked

in degrees, holds a torque ring and is geared to a crank. The torque ring

has a section cut from it and deforms as torque is applied and the resultant

deformation is indicated by a dial gauge. A pointer is provided for registering

the rotation of the vane. A detachable stand is provided to anchor the

instrument. An attachment to securely hold the string of rods is provided. A

calibration curve to convert the dial gauge readings to kg-cm of torque is also

supplied.

LOAD TRUSS 20 TON CAPACITY

MODEL: -GT-083

IS 1888 1962, ASTM D 1194, BS 13779

The truss is of welded 1- girder construction in two halves which can be bolted

together when required. The flower chord, the crosspieces for holding the truss

down and the truss down and the vertical thrust members are all of welded box

type construction with two channels enclosing and welded to an I girder. The

anchorages are of a design tried out and perfected at CBRI- Roorkee. They

consist of semi cylindrical pieces each held down by 3 feet long steel spikes driven

in through holes drilled in the semi cylinder. The spikes enter the ground at about

60 degree to the horizontal, four from each side spaced along the length of the

anchorage. The cross- pieces are moored to the anchorages by channel straps and

bolts. Eight such anchorages are supplied with the 20 ton truss.

SIEVE SHAKER

MODEL: -GT-084, 85, 86

Sieve Shaker

Sieve Shakers, hand operated or motorized, have been designed to provide a

standard sieving action for perfect and quick sieving of soil and other

engineering materials. The motorized unit save considerable time. Time

switch adjustable from 0-60 min., in time intervals of 5 min is provided as

standard along with the motorized sieve shakers.

Sieve Shaker (Manually) 20cm (SL-GT-084)

This is a light, portable but sturdy sieve shaker suitable for bench mounting

the side to side movement to the carrier which can take upto 7 sieves of 200mm

dia is through a train of gears operated by a hand wheel. A heavy fly wheels

ensures smooth operation.

Sieve Shaker (Manually) 20cm, 30cm (SL-GT-085)

Same as above but carrier table & holder suitable to take 20 cm & 30cm (200mm & 300mm) dia sieves.

Sieve Shaker (Manually) 20cm & 30cm

Sieves Box Type (SL-GT-086)

Same as above but carrier table & holder suitable to take 20 cm & 30cm (200mm & 300mm) dia sieves.

'GYRATORY' SIEVE SHAKER

MODEL: -GT-087

Carries upto 7 sieves of 200mm or 300m, 450mm diameter. The shaker is

driven by a ¼ H.P. Motor through a reduction gear immersed in oil.

The sieve table does not rotate but is inclined from the vertical axis and

the direction on inclination charges progressively in clockwise direction. If

the stop pin below the table is removed, the shaker can have a rotary motion.

In addition to this gyratory motion of the table, there is an upward and

downward movement ensuring that each square cm of the sieve is utilized.

A pair of rods and a holder are supplied. The holder can be fixed on the top

of the upper most sieve, and thus the sieve set in firmly held. Suitable for

operation form 230 V, 50 Hz Single Phase A.C. Supply.

'ROTAP' SIEVE SHAKER

MODEL: -GT-088, 089

‘ROTAP’ Sieve Shaker (SL-GT-088)

To make process of sieving simpler and quicker, Rotap sieve shaker is useful ,

this produces circular shaking of the sieves. At the same time the sieves are

tapped. The mechanism for imparting circular action and topping is oil

immersed in a tank and in motorized. The shaker can accommodate upto 7

nos. Sieves of dia 200 or 300mm, 450mm Suitable operation of 230 V A.C.

Single Phase.

ACCESSORIES:

Time switch adjustable from 0-60 minutes in 5 minute intervals.

‘ROTAP’ Digital Sieve Shaker (SL-GT-089)

Same as above with Digital timer 0-99 x 1 minute.

WET SIEVE SHAKER, HAND OPERATED

MODEL: -GT-088, 089

‘ROTAP’ Sieve Shaker (SL-GT-088)

To make process of sieving simpler and quicker, Rotap sieve shaker is useful ,

this produces circular shaking of the sieves. At the same time the sieves are

tapped. The mechanism for imparting circular action and topping is oil

immersed in a tank and in motorized. The shaker can accommodate upto 7

nos. Sieves of dia 200 or 300mm, 450mm Suitable operation of 230 V A.C.

Single Phase.

ACCESSORIES:

Time switch adjustable from 0-60 minutes in 5 minute intervals.

‘ROTAP’ Digital Sieve Shaker (SL-GT-089)

Same as above with Digital timer 0-99 x 1 minute.

STANDARD TEST SIEVES 20CM DIAMETER, (SPUN BR ASS FRAME)

MODEL: -GT-093

IS :460 (Par t-I, II) 1978

Test Sieves is a common laboratory requirement. Sieves are used for sieving of

chemical powders, medical powders, aggregate, sand soil and cement etc.

These sieves are manufactured as per various standards like IS, BS, ASTM, DIN etc.

In Civil Engineering it is a common practice to use sieves for gradation and particle

size determination. Manufacturers brass frame and G.I. Frames Sieves of dia. 200mm,

300mm and 450mm. Normally brass sieves are manufactured in 200cm dia. and frame

is spun brass, The Sieve cloth used is standard SS or prosper bronze wire mush.

The G.I. Frames sieves manufactured normally n sizes 300mm dia. or 450mm dia.

have a steel perforated sheet having accurately punched square holes.

Size Available:

4.75mm, 3.35 mm, 2.80 mm, 2.36 mm, 3.00 mm, 1.70 mm, 1.40 mm, 1.18 mm, 1.00 mm, 212 µm, 180 µm, 150 µm,

125 µm, 106 µm, 90 µm, 75 µm, 850 µm, 710 µm, 600 µm, 500 µm, 425 µm,355 µm, 300 µm, 250 µm,

63 µm, 53 µm, 45 µm, 38 µm, 32 µm, 26 µm, 22 µm. Lid and Receiver for 200 mm dia sieves, made of brass.

STANDARD TEST SIEVES 30 CM DIAMETER, (G.I. SHEET FRAME)

MODEL: -GT-095

IS :460 (Par t-I, II) 1978

Test Sieves is a common laboratory requirement. Sieves are used for sieving

of chemical powders, medical powders, aggregate, sand soil and cement etc.

These sieves are manufactured as per various standards like IS, BS, ASTM,

DIN etc. In Civil Engineering it is a common practice to use sieves for gradation

and particle size determination. Manufacturers brass frame and G.I. Frames

Sieves of dia. 200mm, 300mm and 450mm. Normally brass sieves are manufactured

in 200cm dia. and frame is spun brass, The Sieve cloth used is standard SS or

prosper bronze wire mush.

The G.I. Frames sieves manufactured normally n sizes 300mm dia. or 450mm dia.

have a steel perforated sheet having accurately punched square holes.

Size Available:

Sizes Available : 125mm, 106mm, 100mm, 90mm, 80mm, 75mm, 63mm, 53mm, 50mm, 45mm, 40mm, 37.5mm, 31.5mm,

26.5mm, 25mm, 22.4mm, 20mm, 19mm, 16mm,14mm, 13.2mm, 12.5mm, 11.2mm, 10mm, 9.5mm, 8mm, 6.7mm, 6.3mm,

5.6mm, 4.75mm, 4.0mm, 3.35mm, 2.36mm, 1.18mm, 1.00mm. Lid & receiver in G.I. Sheet frame for 300mm dia.

LOAD FRAME, MOTORIZED, 50 KN (1 SPEED)

MODEL: -GT-066

Triaxial Setup

Triaxial setup has different main components. These components are selected to

complete the setup. In the following pages specifications are given of each

components. Main component requirement for this test are:

I) Load Frame

ii) Triaxial Cell

iii) Lateral Pressure Assembly

iv) Measuring Unit

Load Frames

Load frame is essential equipment for carrying out Unconfined Compression, CBR and Triaxial Shear Tests. Since very

slow rates of strains are required for Triaxial Shear Tests LabTek load frame are made to suit the same. A suitable frame

can be selected from a wide range of LabTek series of Load frames depending upon the type of test and the size of sample.

Each load frame is provided with a standard proving ring adaptor having ½” BSF male threads to suit LabTek range.

Load Frame, Motorized, 50 kN (1 Speed)

It is a single speed load frame designed for 1.25 mm/min strain rate. It

can accommodate Triaxial cells up to 100mm diameter specimen.

Loading capacity is 50kN.Operates on 220V,50Hz supply

LOAD FRAME, HAND OPERATED, 50 KN

MODEL: -GT-065

Triaxial Setup

Triaxial setup has different main components. These components are selected to

complete the setup. In the following pages specifications are given of each

components. Main component requirement for this test are:

I) Load Frame

ii) Triaxial Cell

iii) Lateral Pressure Assembly

iv) Measuring Unit

Load Frames

Load frame is essential equipment for carrying out Unconfined Compression,

CBR and Triaxial Shear Tests. Since very slow rates of strains are required